Moving beyond eco clichés | Bringing about material change

First published by EN Magazine

Moving Beyond Eco Clichés

Part 2: Bringing About Material Change

By Katy Evans and Sam Morris, Ignition

To achieve true sustainable change in exhibition design, the whole industry - clients, designers and suppliers – along with central government, needs to come together to overcome the hurdles facing the development of new, sustainable materials.

These new materials are mostly too expensive right now and don’t yet perform as well as established alternatives. Nor are they available in the timescales, volumes or sheet sizes required. And, as they haven’t been pushed hard enough by suppliers or requested by enough clients, a healthy supply and demand chain hasn’t yet been established for them. Until costs come down or legislation comes in to ban the use of certain materials, the future forecast is a market which will continue to be saturated by products with poor or even zero eco credentials.

Right now, clients ask for eco alternatives but in the same breath say they have less money than pre-pandemic. It’s understandable. Due to the increased cost of living, the pandemic and, in some cases, Brexit, labour costs have gone up a lot, along with pretty much all material prices. As designers, we need to continue to research and suggest alternatives, but clients also need to make a greater commitment - and find the money - to make use of them. It’s a balance that hasn’t yet been struck.

Katy Evans

Client Partnership Director

Sam Morris

Head of Operations

Picking the right material for a job remains more important than picking a material for the sake of it. Cork board is a good example. Yes, it’s natural, but it isn’t durable or good at being handled. We have to be clear about poor material choices effectively causing more waste if they have a short lifespan. Cardboard and paper board have been offered as alternatives to Foamex or Dibond, but they don’t currently have sufficient fire certification for some venues and are not structurally stable enough for re-use.

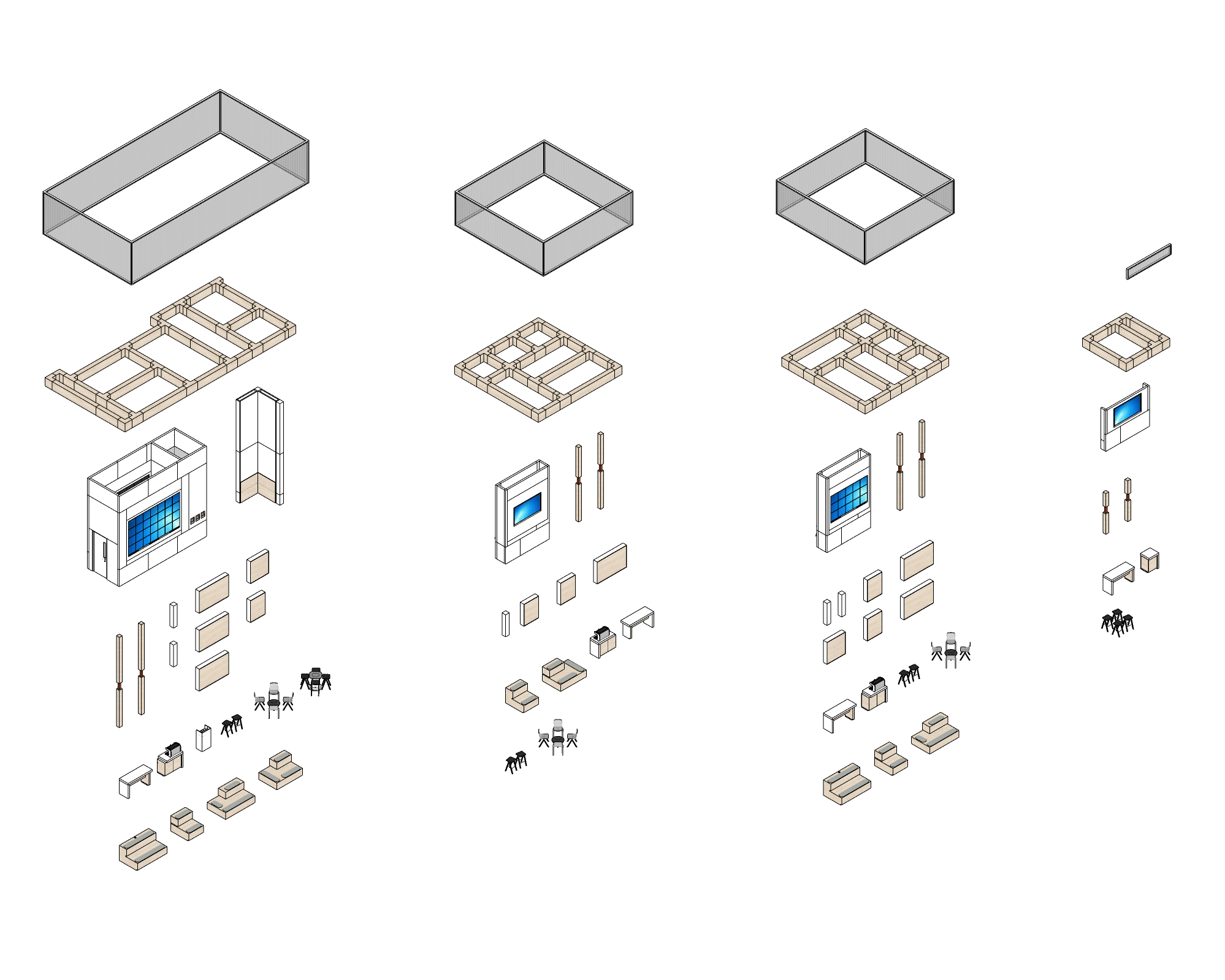

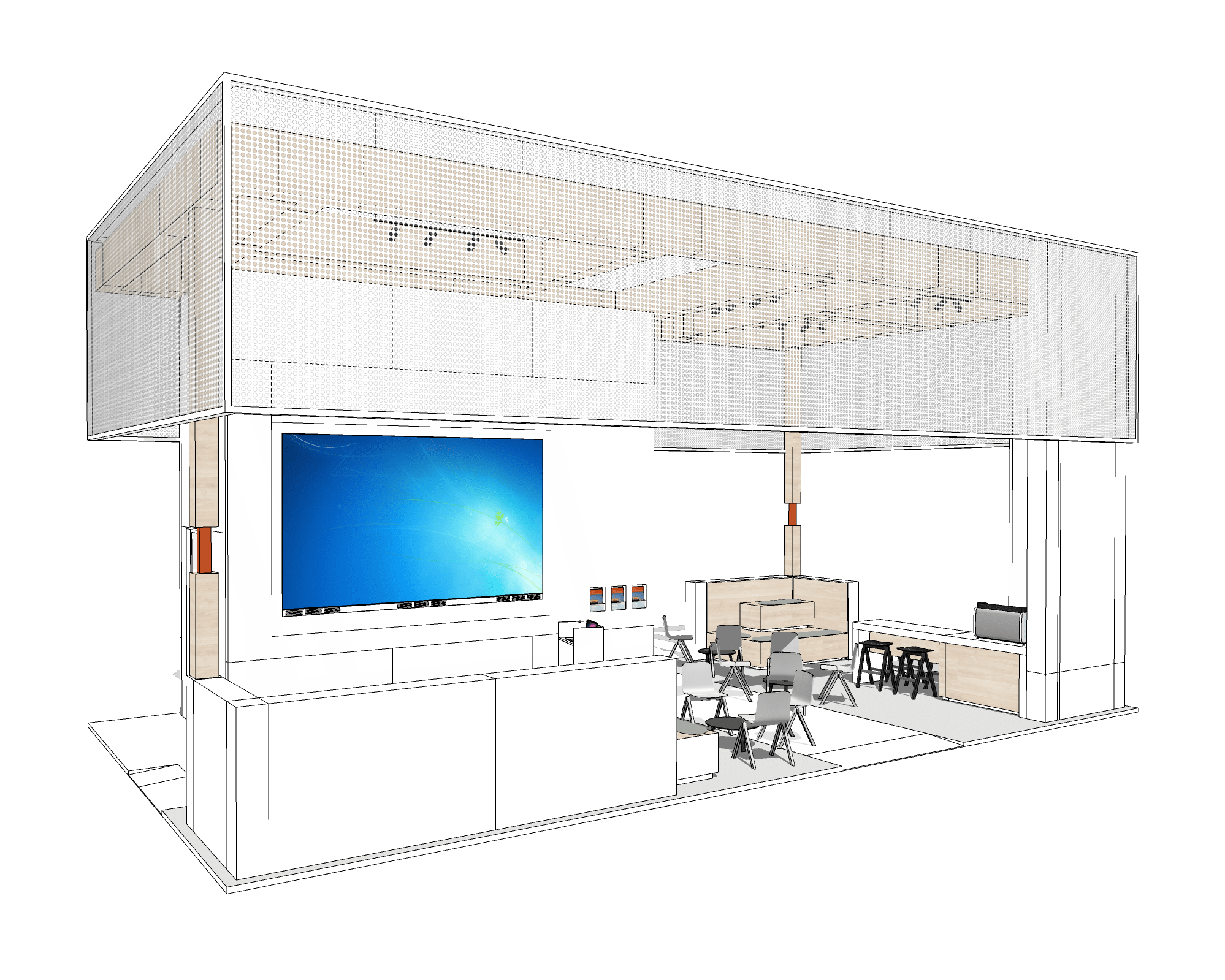

Our solution is a modular kit system, with parts that can last up to 10 years. We’re also starting to design a fully-recyclable version, which would be an amazing threshold to attain. In the interim, a modular kit, plus re-usable rollable graphic panels, Honeycomb board and printing processes that eliminate solvents or waterless ink to limit release of VOCs are all on our list, but we’d absolutely love to hear from more suppliers pioneering sustainable materials that can be used over and over – and which are also affordable!

Better ways to reuse and recycle existing waste products are needed too. Currently, we’re investigating ways to recycle carpet, which US exhibitions still stipulate for stand flooring. We’re delighted to read about supplier progress in this area, such as Ege’s CircleBack, where all used carpet is taken back, with 98-100% of its components recycled. Interface, meanwhile, are launching the Embodied Beauty™ collection, including their first-ever carbon negative products. Carbon capture paints are coming too, such as Celour (UK/South Korea), that captures and stores carbon dioxide from the air.

When it comes to recycling, we’re still looking for good ways to re-use a good number of items. Laminated or spray-painted MDF is challenging, with the only secondary application often for it to be shredded for energy use. Dibond and Foamex are also problematic, as is vinyl for graphics, which is often single use because of the content or printed certification. Using fabric graphics from exhibit banners to make bags is an interesting option and one we’re currently investigating.

In the meantime, we use carpet to line boxes as well as to make storage bags for powder coated metal items. We’re also wrapping metal table bases in reusable fabric bags to avoid using shrink or bubble wrap, though we’re still seeking the same performance levels the latter offer.

We’re certainly using more and more digital display instead of print, which helps with a stand’s credentials. We build furniture to be adaptable to varying booth sizes and apply only a thin layer of surface material to our modular kit. We also off-set our carbon footprint and talk a lot with our clients, but education is still needed to encourage clients to spend money on sustainable materials when what they really want showstopping effects which, in their eyes, translate as ‘something no one has ever seen before’.

We’re definitely moving in the right direction, but there’s a gulf to be bridged. Whilst we’re happy to be the ones in the middle liaising, we need educated and committed clients, binding legal frameworks and more cost-effective materials. We can’t wait to work in a less wasteful industry, but, as with everything in the world of exhibitions, it will only happen through a real team effort - pulling out all the stops, as we’re all used to doing, for every stand and at every show.

Thank you for reading.

We’d love to hear your thoughts. Post a comment below or if you would like to find out more, please do get in touch.